Dachser SE | Memmingen

New Allgäu logistics center – Automated high-bay warehouse

Dachser has been relying on a sustainable heat supply for years.

With the new warehouse, a fully automated high-bay warehouse, the company wants to continue to ensure climate-friendly and resource-conserving operations and continues to rely on e-con and Alois Müller as strong partners for renewable energies.

The new building at the Memmingen site covers an area of 7,500 m² and has 52,000 pallet spaces on 16 levels with a height of 32 meters.

The energy required for operation is mainly generated by a photovoltaic system with an output of approx. 950 kWp. At times when the photovoltaic system does not supply enough power, the warehouse then draws CO2-neutral electricity from 100 percent hydropower. The system consists of 8 inverters and 2,594 modules. It generates an annual energy yield of approx. 1,000 MWh.

The warehouse is also connected to the e-con AG heating plant via the district heating network and can supply the administration area and the high-bay warehouse with regenerative heat from there via the district heating transfer station in the basement of the building.

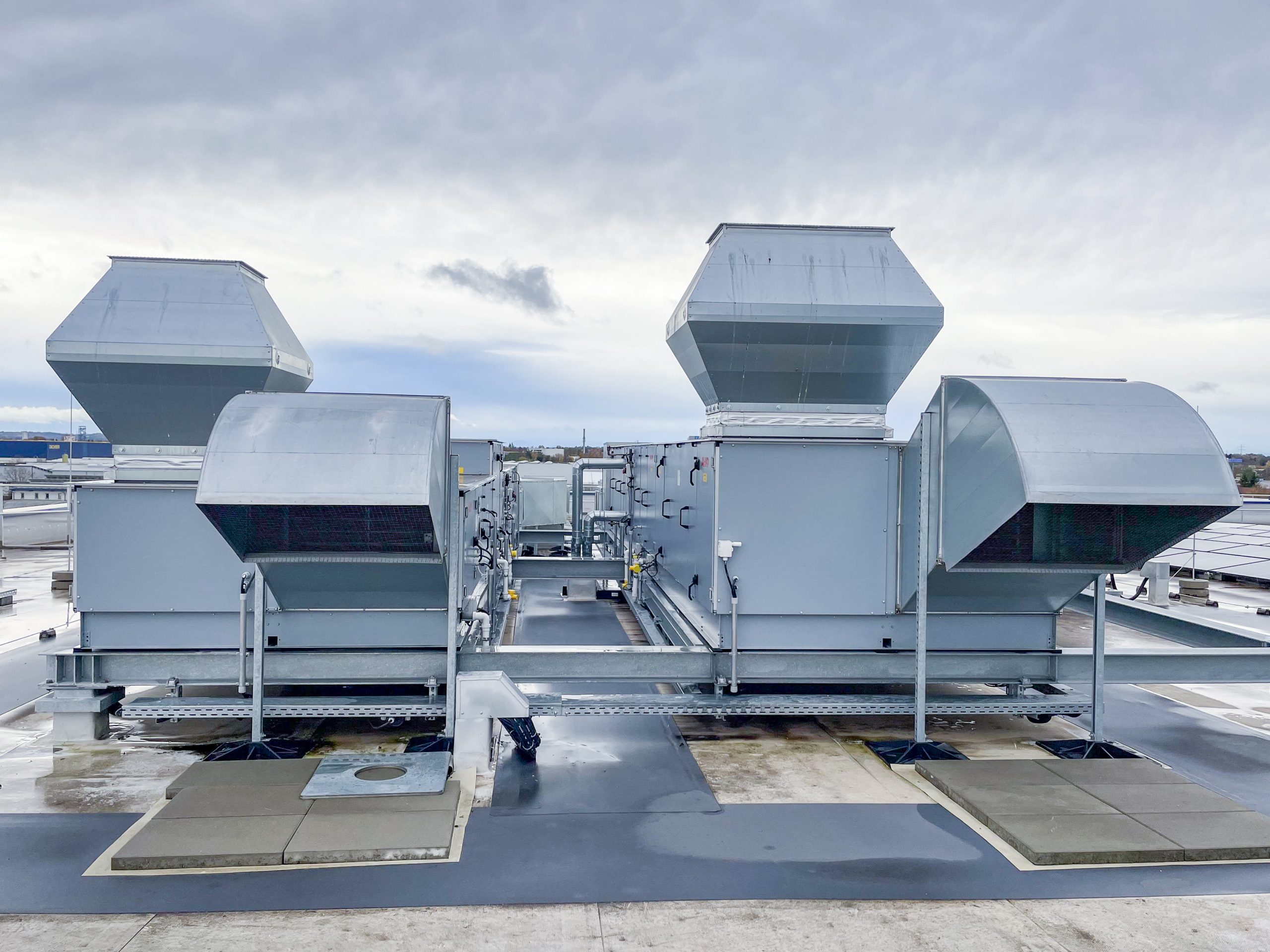

In addition, the ventilation, heating, cooling, sanitary and I&C systems were implemented for the new building.

In addition to ventilation units for offices and the assembly area, a smoke extraction system was also installed. To keep the building warm, radiant ceiling panels and several radiators were installed. Split air conditioning units were installed to cool the server rooms. The sanitary areas, e.g. toilets and showers, were also connected.